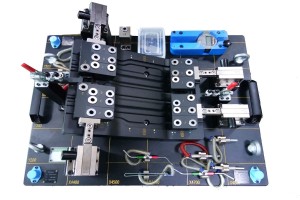

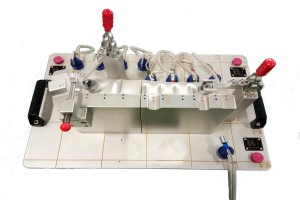

Fixture AL

Part Name: CUSHION SUPPORT BKT 60P CTR

Material: Both base plate and main body are made of Aluminum

Treatment: Both base plate and main body = paint

Cavity: one part out

Lifting method of Fixture: handle

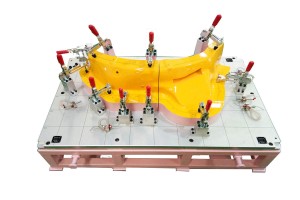

Application: The fixture applicated to automotive stamping part measurement

Lead Time: one month

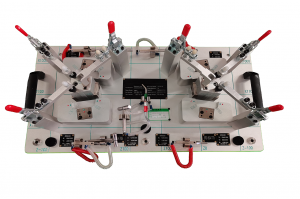

Inspection gauge:

Locating pin: used for Primary datum and Secondary datum

Go/no go pin: hole size check

Feel gauge: flatness check

Checking pin: hole position check

Colour code: surface tolerance identify

Trim line block:used for part profile check

Assist flipped block:surface check

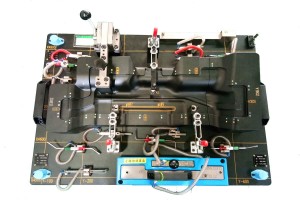

Function of the fixture:

1. Inspect the hole position tolerance of the part.

2. Inspect the relating surface profile of the part.

3. Inspect the relating trim of the part.

4. Inspect the other relating dimensions of the part.

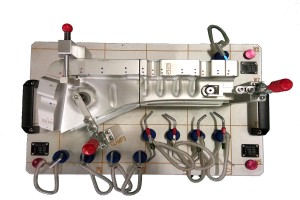

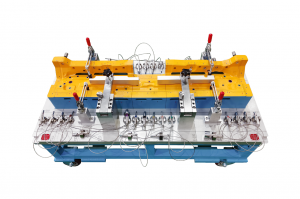

Environment:

The fixture should be put in a stable temperature and clean environment to keep and use.

Background:

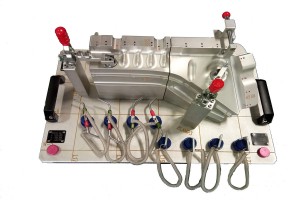

Both base plate and main body of the fixture are made of Aluminum and through anodized treatment, so the fixture is wear-resistant, not easy to scratch and has a long service life.

Consider of part and fixture dimension and fixture weight, we designed the lifting method of fixture with adding handle, which is easy to operate for users. Besides this, before fixture shipment, the fixture is sufficiently retained using bolts or dowels to ensure the safety. We also need to complete CF Shipping Approval sheet and sent to be reviewed and approved by our customer, such as correct 3mm gap to panel on checking fixture, alignment plates correct and securely mounted on checking fixture and CF correctly colour coded and marked up, etc.

If you have interest or want to know more about Aluminum checking fixture, please do not hesitate to contact us. We are pleased to discuss with you.